Stained Glass Panels

When

I designed my entertainment center, I knew I wanted to incorporate

stained glass panels in the doors. At the time, I naively

assummed I could just visit my local glass supplier and order custom

stained glass panels. Things are never that easy, and my glass

supplier told me that, as far as he knew, custom glass panels like I

wanted were simply not available. He suggested I visit a stained

glass shop where he thought they might be able to fabricate my

windows. That visit was quite a learning experience. I was

lucky because the proprieter was a very nice man who suggested that

rather than have him make the glass panels for me, why don't I learn

how to make them myself. I thought, well, why not?

I have to admit that at first, working with glass was a bit

intimidating, and in many ways, it is very different from

woodworking. But in many other ways, it is very similar.

Precision and accuracy are key to both, as is having someone to hold

your hand, mentor and guide you. I took a short class in basic

stained glass, nothing as elaborate as these panels, but learned enough

to become somewhat confident I could make my own panels.

Since this entertainment center project was done over two years, it was

quite a while before I was finally ready to make my windows. In

the meantime I completed quite a few other woodworking projects, but

the entertainment center sat for most of that time covered in blankets

in a corner of the shop, waiting for me to get back to it. When

the time finally came to build these windows, I was dragging my feet

because I was worried I could pull this part of the project off.

As with many "learning experiences," the first panel took me

about 8 hours to complete. But the second panel only took an hour

and a half! I'll share just a few pictures of the panel-making

process because I'm still not yet confident enough in my stained glass

skills to write with any authority about it. But I will say that

after I got the hang of it, it was a truly enjoyable experience.

|

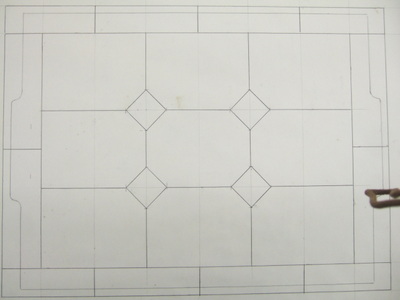

An accurate drawing of the glass panel, dimensionally correct, is the starting point.

|

|

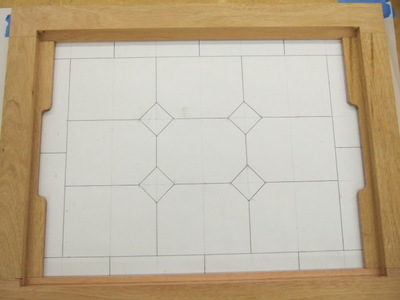

Here

you can see the drawing of the stained glass panel under the door

frame. If my glass panel comes out exactly the same size as the

drawing, it will fit perfectly in the frame.

|

|

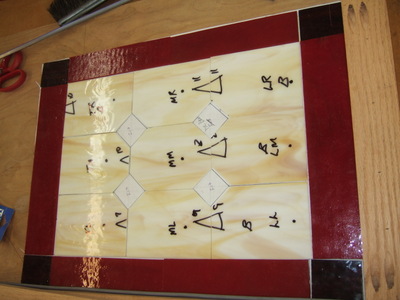

Here

is a picture of all the glass pieces after being cut laid in the

approximate arrangement they'll have in the final panel.

|

|

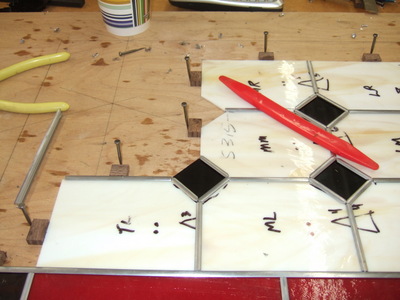

Here

I'm fitting lead came around the individual pieces of glass. I'm

doing this in a squaring jig I made out of plywood. The nails you

see are tapped into the plywood with a small wood block between the

nail and the glass. These hold the glass while I build the panel

starting in the lower left corner out to the upper right corner.

|

|

Here

is the panel ready for soldering the joints. You can also see the

squaring jig I fashioned out of a couple of scraps of wood. I

used a soldering iron with flux to solder each joint where one or more

pieces of came come together. After soldering both sides, the

panel becomes rigid, but it is not yet finished. The final step

is to apply a cement to the entire glass panel, both sides. and work

the cement into the joints where the glass goes into the came.

After the cement drys, it hardens making the panely weatherproof.

This technique goes back nearly 1000 years and is well documented on

the web.

|