|

Here are the laminations

ready for glue up for two complete chairs. All laminations are

white oak and have been resawn and thickness sanded to a uniform

thickness of 1/8 inch. It is very important to thickness sand

these laminations to assure a very consistent thickness so there will

be no voids during glueup.

|

|

The glue used for bentwood lamination is absolutely

critical. I use a two part glue alled urea formeldhyde.

This is the same glue commonly used in the plywood industry, but

formulated to cure at room temperature. Unlike other glues, this

glue forms an absolutely rigid glue line resulting in virtually no

creep or spring back after the laminations are removed from the forms.

I use a small paint roller to place an even coat of glue on all mating

surfaces. To protect the two outside surfaces (e.g.: the outside

faces of the resulting glue lam) I covered each surface with packing

tape. This glue is very difficult to remove from anyplace you

don't want it to be, so using tape to protect surfaces is essential.

|

|

Here I'm apply a fairly generous amount of the glue to the

glue side of the sheet of veneer containing the marquetry image.

Since this veneer is only about 1/42 inch thick, you normally only

apply glue to the substrate when working with veneer. This is the

one exception to that rule because applying the glue over the marquetry

image ensures that any tiny spaces in the images will be filled with

glue causing the joints to virtually disappear.

|

|

At this point all the surfaces have glue on them and I'm

preparing the stack to go into the form. To keep the stack from

moving as pressure is applied, I'm using packing tape to bind the

package of laminations together in the center.

|

|

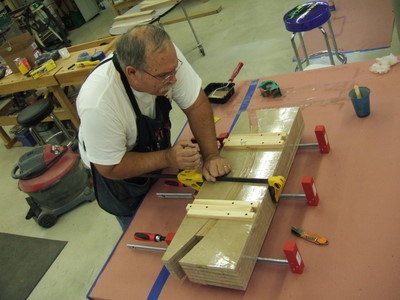

Here you can see the process of bringing the two halves of

the forms together. Notice the system I use to ensure both forms

remain in alignment as pressure is applied by the clamps. Also

notice that the clamps under the forms are ready to go to apply uniform

pressure as soon as I use the yellow clamp to bring the two halves

together. This picture also shows how everything is coverd with

packing tape to keep the glue from sticking where it does not belong.

|

|

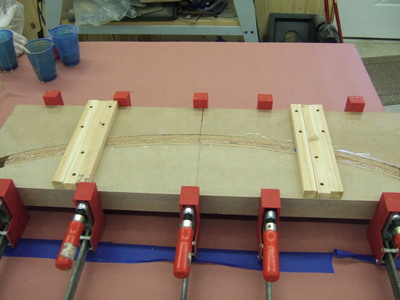

This is a picture of one of the rockers in clamps waiting for the glue to dry. I leave the assembly clamped overnight.

|

|

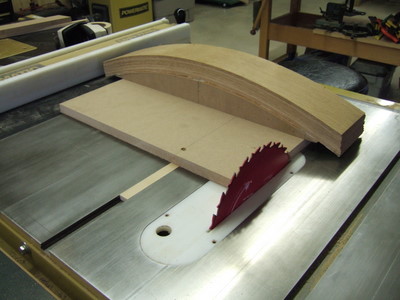

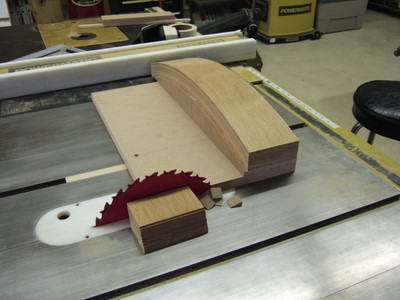

I made the back rests longer and used this jig on the table

saw to trim the ends to exact length and at a relative angle of 90

degrees. This sled took about 4 hours to build and the trimming

operation on the back rest pieces about 10 minutes to complete.

This really is the nature of chair making. You spend a lot of

time making forms, jigs and fixtures. The rule is that it will

usually take you a lot long to make these things that it will spend

using them. Of course, these can be reused later to make another

chair and the time you spend making the next chair is reduced by the

time it took you to make the jigs and fixtures. The only trick to

this is to keep careful notes on what each jig and fixture is

for. You may not get around to using it again for years and it is

very easy to forget over that much time.

|

|

Here is a set of laminations for one chair after all the trimming and cleanup was done.

|