|

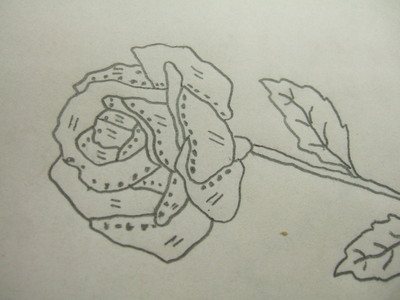

Here is a closeup of one of

the roses.

|

|

Here is the working

cartoon of one of the roses. Each rose has 20

individual parts, and with 10 roses, the marquetry has a

total of 200 individual parts.

The dots you see in the picture designate where each part

is to be sandshaded. The parallel lines you see

indicate grain direction.

|

|

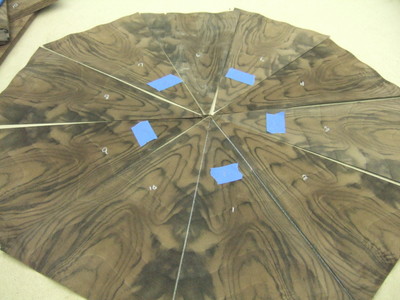

The process begins with

a stack of at least 10 pieces of veneer. Note the

plastic 10-way radial match template on the left.

The template is used to set the width of the mirrors you

see that I've secured temporarily with a piece of blue

tape to keep the mirrors at about the same angle as the

template. By moving the mirror around the surface of

a sheet of veneer, I can visualize the pattern that will

emerge when all 10 pieces are cut from below where the

mirror is positioned, then arranged in a radial match.

|

|

After I've located the

position on the stack of veneer where I want to make the

cut, I use a veneer saw to cut thru all 10 pieces of

veneer at once. Here you see the packet of veneer

just after I completed the first cut. Next I'll use

a sanding block on the edge to sand away any rough spots.

|

|

Here I've arranged the pieces as they'll be

in the finished table top.

|

|

The process of

assembling the radial match begins by using blue tape to

secure two edges together.

|

|

Next I flip the taped pieces together

and use veneer tape to secure the seam.

|

|

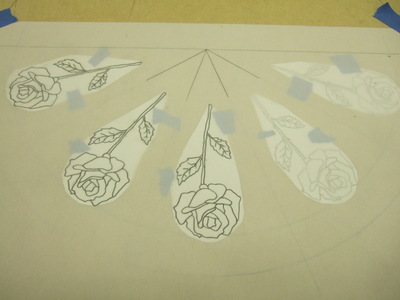

Here is the fully taped veneer top. I

created one rose image and scanned it into my

computer. Next I used an image processing program to

make six copies of the image each scaled

differently. Here I've placed this over the top

trying to decide which of the scaled images best fits.

|

|

Having selected the size of the rose I

want, next is made several copies and cut each out.

I've positioned each copy under a piece of vellum

arranging the roses as I want them to appear in the

finished project. Note that I'm working on 1/2 of

the table top. When I actually cut the marquetry

images, I'll fold the table veneer in half and only cut

five roses out. Later I'll unfold the veneer giving

me 10 roses that are a mirror image of each other.

In this particular step I'm happy with the position of the

roses and I'm using a pencil to copy each rose on the

vellum. When complete, I made several copies of the

image to be used as you see below.

|

|

This step is a bit tricky to explain.

I've taken a copy of the cartoon and layed it on top of

the folded radial match veneer, then secured it in place

with blue tape. I've selected the veneer I want for

the rose petals, leaves, and branch. I've built on

top of each image a packet of veneer out of which the

image will be eventualy cut.

Note the poplar veneer I've placed over where the leaves

are. There are actually two pieces of veneer,

back-to-back, for each leaf. I need two because I'll

be cutting two leaves at the same time. The same

logic is repeated for the rose petals and the

branch.

I like to use clear packing tape to hold all the piecies

in place. I've found that clear packing tape holds

everything securely, and provides some lubrication to the

scroll saw blade as I'm cutting out the packets.

|

|

Here is the finished packet ready for the

scroll saw. The image I'll be cutting lies exactly

over the packets of veneer I've arranged under it and the

background veneer.

|

|

I didn't take any photos of the actuall

scroll saw work, but here you can see the end

result. The dixie cups you see placed above each

rose contain the individual parts that I cut from the

pattern. Since each rose has twenty components, and

I've cut two roses simultaneously, each stack of cups

contains forty components. I had to resort to dixie

cups because the shear number of components made it too

difficult to use the normal grid system I would use for

fewer components.

|

|

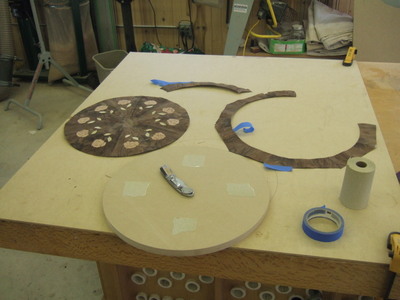

I've skipped a lot of steps, but here you

can see the finished skin just after I trimmed it using

template I cut from MDF you see in the picture. To

hold the veneer securely under the template I placed a few

pieces of sticky sandpaper, then trimmed with a utility

knife. The trimmed skin is still oversized and will

be trimmed a final time after the final glueup.

Note that you are looking at the "glue" side of the

skin.

|

|

Here is the top just after coming out of

the vacuum press. All the veneer tape you see will

have to be carefully removed.

|

|

Removing the veneer tape is done by

thoroughly soaking the tape with water and waiting for the

glue to be reactiviated. I carefully scrape the wet

veneer tape off using a specially sharpened scraper you

see here.

|

|

After an hour or so of scraping, the tape

is removed and the top is ready for sanding.

|

|

After applying the solid wood edge and an application of top coat.

|