|

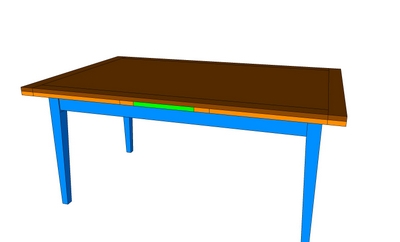

Here is a color coded image of the table that I will use

to explain the basic operation. Notice first that

there are two tops, an upper top in dark brown that is the

actual table top, and a second top under the first that

consists of three sectons: a middle section in green

and two draw leaves at either end in light brown.

|

|

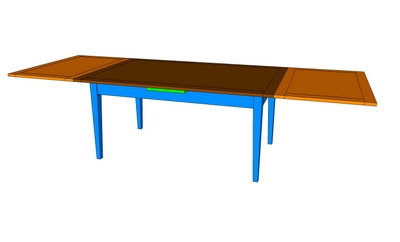

The table with both draw

leafs in the extended position. Notice the key

element of this design is that as each leaf is extended,

when it reaches the end of its travel, it snaps into a

position that is exactly level with the actual table top,

effectively extending the length of the top. In

effect, each draw leaf must rise along a ramp system the

thickness of the table top such that when it reaches the

end of its travel along the ramp each leaf is at the same

level of the top. This is the key to the tables

operation and I'll explain more about how this works a bit

later.

|

|

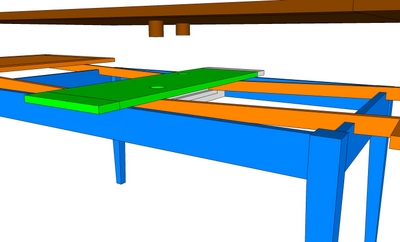

One of the key reasons

this can work is that the top actually floats on the table

and is held in position by two pegs you can see

here. The pegs in the table top are not really drawn

to scale. In actual practice, I used pegs that were

1.25 inch in diameter. The holes in the center

section are actually slightly larger in diameter.

The fit of the pegs into the holes is key because they

both must hold the table somewhat firmly in position, yet

allow the top at either end to rise as either leaf is

pulled out. When the leaf reaches its fully extended

position, it is the top that snaps back down as the leaf

is extended past and no longer supports the top.

|

|

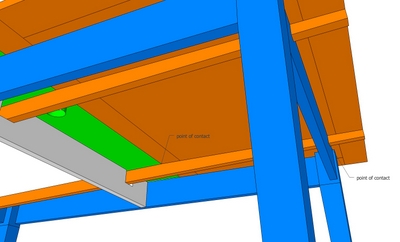

There are several things

of note in this picture. First, notice that the

slide changes thickness from about 2 inches toward the

middle to slightly less than 3/4 inch when it reaches the

end of the leaf. This change in dimension forms the

"ramp" that allows the leaf to rise as it is pulled

out.

Second, notice that there are two points of contact that

the ramp makes with the table base. On the

fixed center leaf, the ramp contacts the leaf at the point

shown. Note that it does not make contact in the

notch that is cut thru the center brace thru which it

passes. The notch in the center is more of a

side-to-side guide. Note that the other place the

ramp contacts the table at the bottom of the notch cut

into the apron. The depth of the notch in the apron

must be extremely precise because that depth, along with

the thickness of the ramp at the point of contact, are

what establishes the height that the leaf will rise when

it if fully extende or fully inserted.

|

|

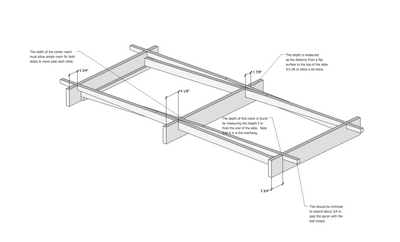

Here is an exerpt from

my shop drawings that shows the particular dimensions from

the table I built.

|

|

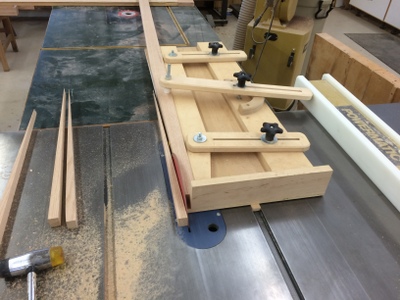

I used my tapering jig to cut the angle

for the slider ramps. This was an extremely fussy

cut that had to be dead-on to also match the depth of the

notch in the apron so the leaf would be positioned at

exactly the same height as the main table top when the

leaf is fully extended.

|

|

Here are a couple of pictures showing

how the slides attach to the leafs and pass thru notches

cut into either apron as well as a center divider.

There is enough room in the center divider to allow the

slides to easily pass past each other, but not so much as

to allow the slides to rack as they are moved in and out.

The second picture shows how the slides are secured to the

leafs using screws and glue. If you look carefully

at the bottom image, you'll note that the slide extends to

the end of the leaf. Later, I trimmed the slide so

it only sticks past the apron by about an inch, but during

fitup, I left it long.

One other important thing that is not shown is a stop that

I fabricated to not allow the slides to extend too

far. I made a couple of stop blocks that were

screwed to the slides that prevent them from passing

completely thru the center apron.

|

|

Here is the table just prior to

staining. These pictures show the two alignment

holes in the center section. Also note that in the

bottom picture, the leaves are fully extended. Had

the top been in place, both leafs would have risen to be

in exact vertical alignment with the top.

|

|

After finishing and almost ready to go

out the door. It's difficult to see, but you'll

notice that the top of each slide appears to be

unfinished. That's because I've installed a thin,

low friction UHMW tape to these surfaces to allow the

mechanism to work with as little friction as

possible.

I don't have a picture that shows it, but I also installed

several strips of UHMW tape to the bottom of the top

itself. As the leafs are pulled out, these strips

effetively lift the top very slightly above the leaf so

there is no wood to wood contact.

|