|

The

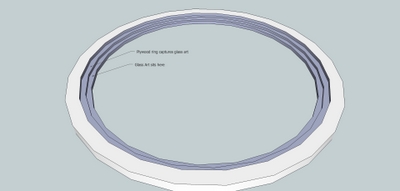

basic idea is to create a circular frame with two ledges. One

ledge, the lowest, will hold the art work. The upper ledge will

hold a 1/4" plywood circular keeper that will be secured from the rear

with wood screws, capturing the glass art in a wooden sandwich.

|

|

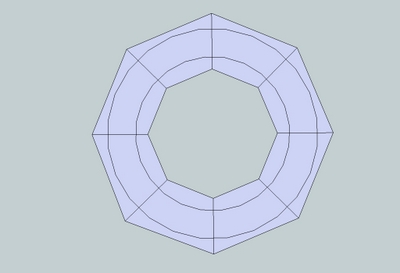

How

do you turn a straight piece of lumber into a circle? In this

case, I glued up eight segments using splines to create the shape you

see, then using my router with a circle cutting guide, I exracted the

circular frame.

|

|

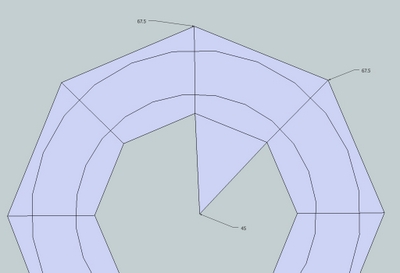

A

circle is divided into 360 degrees. If I want to cut the circle

into eight equal pieces, each piece will have a 45 degree angle as

shown. To cut the angles out of each straight piece. I needed to

set my miter saw to 67.5 degrees (or its compliment 22.5 degrees.)

|

|

Here is the stained glass artist getting a woodworking lesson!

We put a 1/4" box joint blade set in the table saw and adjusted the

tenon cutting jig to cut half the spline joint in the center.

Because it is virtually impossible to make this adjustment precise, we

marked each piece with a reference mark then always placed the

reference mark agains the fence of the tenon cutting jig.

|

|

Here

you can get an idea how the splines work. Because it was nearly

impossible to clamp this, I used hide glue that has a very strong tack

and slow setting time. This allowed me to press the joint

together by hand and set it aside to dry. As long as you press it

for three or four minutes, the tack strength of the hide glue does a

good job holding the joint closed. Of course, it would have been

preferable to clamp each joint, but this technique worked great.

|

|

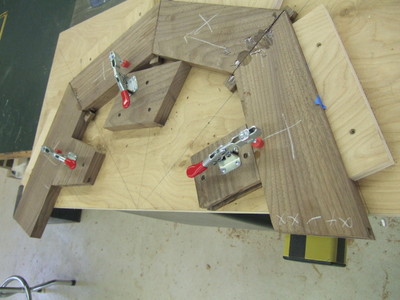

No matter how accurate you think

your miter saw is, the reality is that each angled cut will introduce a

tiny amount of error. Multiply an error even as small as 1/10 of

a degree, over 8 joints, times two angle cuts per joint, results in a

cumulative error of 16 * 1/10 degree, or 1.6 degrees of error.

That will make it impossible to completely close all the joints.

The solution to this problem is to make the final glueup out of two

halves, then use a jig like I show here to trim each half to be

perfect.

This jig took an hour or so to build, and was used for only two cuts,

but allowed me to create perfect joints. Each half is trimmed as

you see, then both halves have splines cut as I showed above.

|

|

Cutting the splines in each half

could not be done with the tenoning jig. I had a fence laying

around that fits over my table saw fence. By securely clamping

each half to this fence, I was able to secure the object so it could

safely be passed over the dado blade.

|

|

Now that the glueup is complete

and sanded, I can go to work with my router and a circle-cutting

guide. Starting at the outside, I cut the outside diameter first,

then the inside diameter, then the ledge for the glass art, and finally

the edge for the plywood keeper.

|

|

Here I've used my router and

circle cutting jig to cut a plywood ring out of 1/4 inch plywood.

The outside and inside diameters of the ring match exactly the recess I

created in the fram.

|

|

Here is the final result after finish sanding, boiled linseed oil, the three coats of General Finishes ArmRSeal top coat.

|