|

Here is a closer picture of the

parquetry in the chair-back. The curved back is made

from 1/8" cherry strips that

are laminated in a form. The top lamination is the

parquetry

pattern made from 1/42" veneer.

|

|

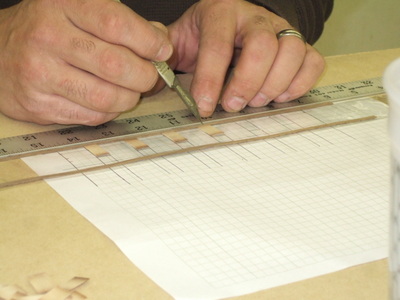

The process starts by drawing the

pattern on a piece of graph paper. Clear packing

tape is placed over the graph paper sticky side up and

fixed so it will not move. Each piece of the pattern

is "picked and placed" on the sticky side of the packing

tape, one piece at a time.

|

|

Sand shading is done in a batch to give

the feel of depth to the overall image. Each of

these strips will be cut into individual strips after

shading. It is simply more efficient to shade the

veneer this way rather than first cutting to final size

then shading.

|

|

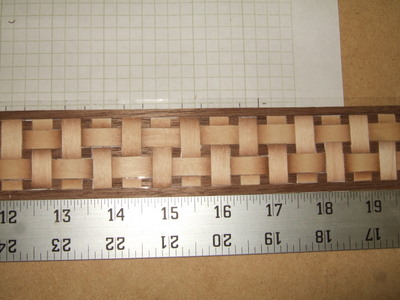

With patience, after an hour or so you

end up with something like this. Note that all the

pieces are stuck to the sticky side of the packing

tape. The packing tape will remain in place

throughout the bent lamination process.

|

|

A closer look.

|

|

Urea Formaldehyde glue is used to create

the laminated chair back. This glue has a long

working time and forms an absolutely rigid glue

bond. A rigid glue bond keeps the curved lamination

from springing back after removal from the form.

|

|

We made several forms to speed up the

process. Each chair back lamination consists of

seven 1/8 in thick pieces of cherry. The parquetry

pattern (still on the packing tape) is the outermost

lamination.

|

|

After drying in the form for 12 hours

the chair back is taken out and the packing tape is

removed. You can see we added the wider cherry bands

on either side of the parquetry pattern to give the final

appearance that the parquetry image is embedded in the

solid cherry chair back.

|

|

All the curved parts for the chair backs

are glue lamination are intentionally made over

sized. We made several table saw jigs like the one

you see here to safely trim each piece to the correct

length. The curve on the form exactly matches the

curve on the piece being cut. This all begins with a

single master template from which me make both the gluing

form and these cutting jigs.

|

|

After final assembly it is time for

finishing. The finish we selected was a very thin

seal coat of shellac followed by boiled linseed oil.

After the linseed oil is fully dried a polyurethane top

coat is applied.

|